CSI's pull through welder system is durable and reliable yet simple to operate and maintain. It can be customized to suit specific production requirements.

The automated pull through welder system is fully integrated, with improved process control from fit up through tack and weld. Utilizing advanced methods of motion control and sensing, this system is capable of producing consistent and higher quality beams with reduced set up time and operator dependence.

For inquiries, please call us at 905-681-1580 or send an email to

General Capabilities

The overall system can be configured to suit your production needs with a range of capacities and levels of process automation. It is perfectly suited for structural, large vehicle, and custom beam applications.

Features:

- Advanced technology for industry-leading product quality

- Extremely rigid structural tube framing construction

- Highest quality standard components and engineering incorporated for machine reliability and life

- Operator-friendly HMI and integrated LAN

Welder Station

The field-proven process easily meets construction and military transpotation codes for dimensional and weld quality.

More features:

- Positive and negative taper capable

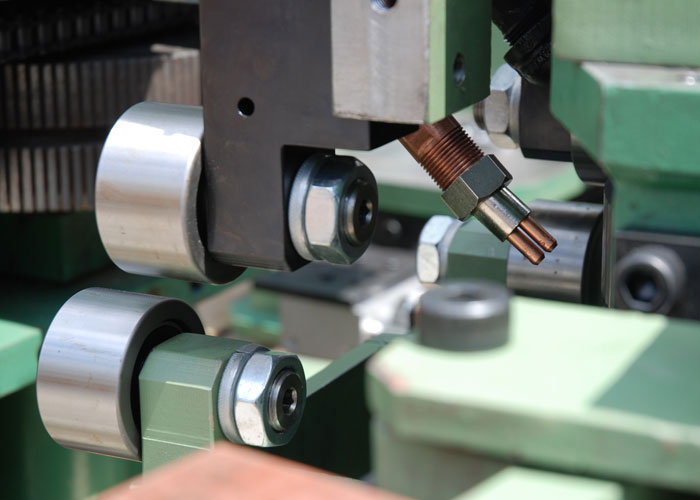

- Servo-positioning weld head with non-contact digital seam tracking for optimum weld quality even with material variations

- Master and slave drive for weld heads allows for linear passage of the beam through the weld station

- Variable hydraulic clamping on flanges and web

- Integrated twin wire sub arc welding with flux deposit and recovery

Pull Through Station

Every aspect of this station has been evaluated and redesigned to reduce set up time while improving the quality of the product.

Features:

- Fully-synchronized in and out feed conveyors in perfect synch with both weld head drive roller sets — no more beam distortion caused my shimmying

- Independent motion of each weld head produces consistent indivudual seam and beam to beam welds

- Heavy industry-grade ball screws, servos and pneumatic compnents improve reliability

- Auto clamp and unclamp reduces set up time to improve "weld-on" percentage of total cycle

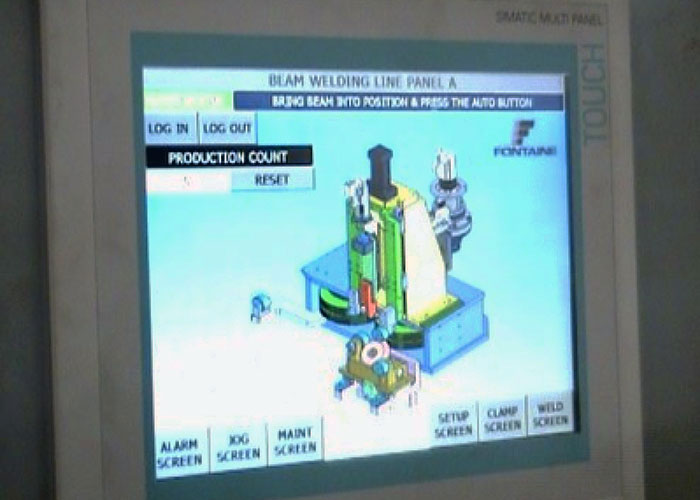

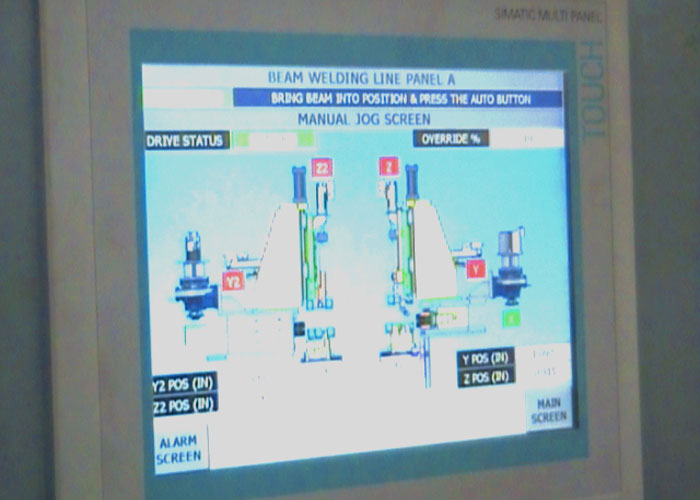

Control System

Developed with ease of operation, productivity, and beam quality in mind, CSI's motion control expertise is evident in the design and functionality of the welder's control system.

It uses Siemens industrial controls: a Siemens PLC, six servo mortors and drives, and a 10" Siemens touch screen with a CNC operator keyboard. The field devices that come with the system are all solid state for reliability. All the software is written by CSI and we can customize it to suit your needs.

Features:

- Recipe-driven weld and clamp set up with memory to save up to 100 beams set ups for automatic beam loading

- Flexible operation of stations in manual or auto mode

- Manual controls for all axes

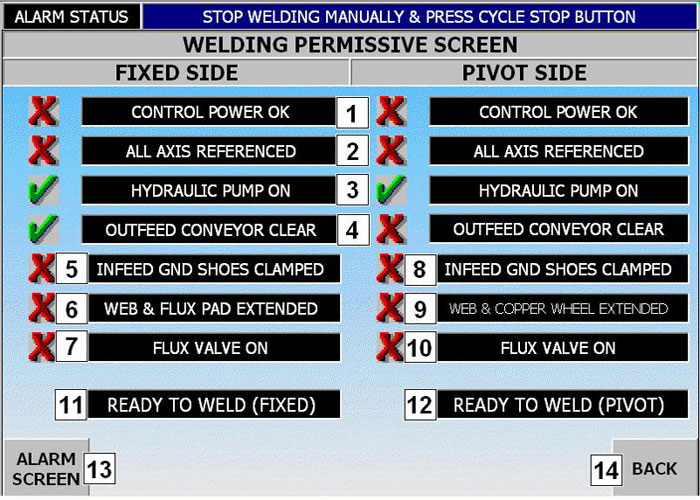

- Descriptive HMI displays for system status and fast troubleshooting

- "On the fly" beam feed rate change with full drive and conveyor customization

- Network connection to your existing control logics PLC

Optional Equipment

Web Seamer

Servo-driven in-feed rollers and automatic clamping allow for quick and easy seam welding. The system comes complete with automatic weld flux dispensing and recovery units, and features a selection of flux beds: copper, flux, and flux bag.

Fit Up and Tack

Uses localized web and flange claming for a tight fit at the tack station ensures quality alignment and operator-appropriate controls ease of function. This is the first step to producing a better beam.

Features:

- Magnetized flange alignment rollers and web plate lift for easy lift up

- Strategically located alignment and clamping features ensure dimensional and structural integrity of the finished product

- Ruggedly built to endure harsh environments

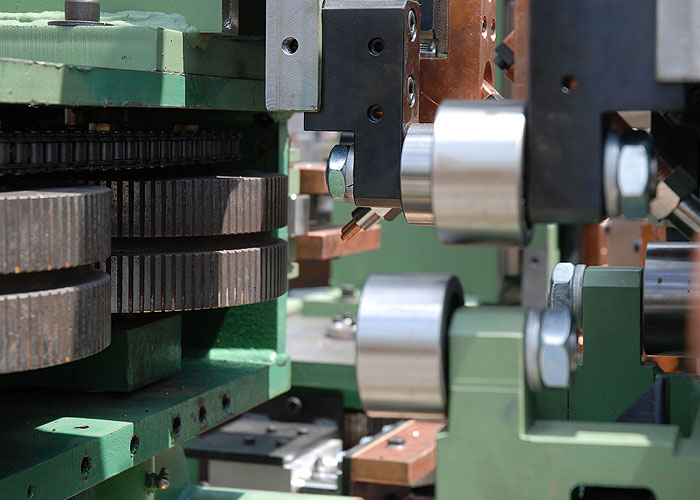

Pull through welder system

Welder, side view

Welder, top view

Welding head, close up

Welding head, another close up view

Angled beam during welding

Angled beam after welding

View of the control panel

System status display

System status display: Jog screen

Operator "Weld Permissive" check list

Product Specifications

| Structure |

Welded HSS fabrication |

| Beam drive system |

Two hardened knurled drive wheels |

| Web height adjustment |

Ball screw with AC servo |

| Welding tip adjustment |

Ball screw with AC servo |

| Pivot |

+/- 15 degrees with respect to the beam |

| Pivot lock |

Hydraulic — allows welding to the end of the beam |

| Welding heads |

Two-axis AC servo with seam tracking technology |

| Controls |

Siemens PLC, motors, drives with 10" colour LCD screen |

| Hydraulic system |

Self-contained, 15 HP variable displacement pump at 2900 psi |

Machine Capacity

| Web thickness |

1/8" |

1/2" |

| Web width |

6" |

72" |

| Web taper |

15 degrees |

| Flange thickness |

3/16" |

1 1/2" |

| Flange width |

4" |

20" |

| Beams length |

8' |

60' |

| Beam weight |

up to 12,000 lbs |

| Weld fillet size |

1/8" |

5/16" |

| Welding speed |

20' per minute |

150' per minute |

PDF download (right click to save): Pull Thru Welder System brochure

If you are interested in learning more, please call us at 905-681-1580 or send an email to

We can email you a link to the video of the welder system in action and we can also arrange a demo for you to see the machine.